Product

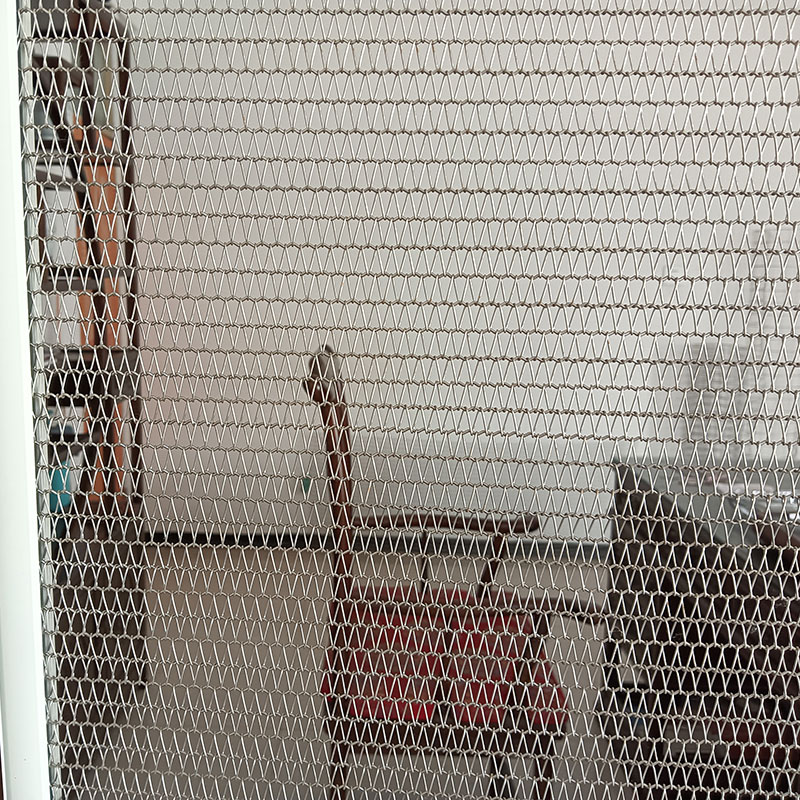

stainless steel Knitted wire mesh sock

Materials of knitted wire mesh

Knitted wire mesh is available for various materials. They have different advantages and can be used in different applications.

- Stainless steel wires. It features acid and alkali resistance, high temperature resistance and can be used in harshest environments.

- Copper wire. Good shielding performance, corrosion and rust resistance. Can be used as shielding meshes.

- Brass wires. Similar to copper wire, which has bright color and good shielding performance.

- Galvanizes wire. Economical and durable materials. Corrosion resistance for common and heavy duty applications.

- Nickel wire.

- Other alloy wire.

- Polypropylene. Plastic material for lightweight and economical. Low cost and corrosion resistance.

The machine producing knitted wire mesh is similar to that machine making sweaters and scarves. Installing the various metal wires onto the round knitting machine and then we can get a continuous circle knitted wire mesh.

The knitted wire mesh can be made of round wires or flat wires. The round wires is the most commonly used type and the flat wire knitted mesh is commonly used in the special applications according to customers' requirements.

The knitted wire mesh can be made of mono-filament wires or multi-filament wires. The mono-filament knitted wire mesh features simple structure and economical, which is widely used in the common applications. The multi-filament knitted wire mesh has higher strength than the mono-filament knitted wire mesh. The multi-filament knitted wire mesh is commonly used in the heavy duty applications.

The circle knitted wire mesh is pressed into flattened types and sometimes, they are crimped into ginning knitted wire mesh The ginning has different shapes, width and depth. They can be used in various industrial applications for filtration.

Features of knitted wire mesh

- High strength.

- Corrosion and rust resistance.

- Acid and alkali resistance.

- High temperature resistance.

- Soft and won't hurt the mechanical parts.

- Durable and long service life.

- Good shielding performance.

- High filtration efficiency.

- Excellent cleaning capacity.

Applications of knitted wire mesh

Knitted wire mesh is widely used as liquid-gas filtration materials in various fields of industries. Compressed knitted mesh is commonly used as filtering materials in the industries. It can be used as engine breathers in the vehicles. Knitted wire mesh can be used as shielding mesh in the electronics and other fields. Knitted wire mesh can be used to eliminate the mist as the knitted mesh mist eliminator or demister pad. Knitted wire mesh can be made into knitted cleaning balls to clean kitchenware and other mechanical parts needed cleaning.